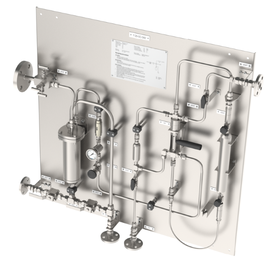

Super Duplex (SDSS) Sampling Systems

Sampling system made of Super Duplex (SDSS) are designed to provide better corrosion resistance.

These sample systems in Super Duplex make connections to process pipelines, tanks or reactors mostly on offshore FPSO applications and downstream processing plants.

The benefits of manual sampling are:

● Quality control, reducing costs by process optimization

● Taking representative samples and get better results of analysis your petrochemical products

● Preventing production loss

Mechatest has been awarded a contract for the engineering and productions of Super Duplex (SDSS) manual sampling connections for one of the biggest FPSO manufacturers in the World.

On a FPSO vessel there are Super Duplex (SDSS) sample connections necessary for product quality measurements and process optimization, Mechatest designed for these FPSO projects Super Duplex

(SDSS) liquid and gas sample systems due to long lifetime and long term maintenance free sampling.

Super Duplex (SDSS) Liquid and Gas Sampling Systems

Proud to improve the Super Duplex (SDSS) liquid and gas sample quality and analysis on the FPSO projects. We designed Super Duplex (SDSS) sampling systems for directly take of samples from a tank, container, pipeline, reactor or mixer at FPSO vessels. We always improved our Super Duplex (SDSS) sampling systems:

- Creating closed loop systems which provide a safe, controlled environment

- Adding sample (needle or process) purge options

- Fixed volume sampling, which minimizes both waste and costs

- Design spring return valve solutions

- Simplifying designs, making the sampling of liquid and gas more efficient

- Proper discharge of excess liquid or gas prevents unwanted pressure build-up in the system

These modern solutions simply regard the Super Duplex (SDSS) sampling connections themselves. Our worldwide reputation rests on the combination of excellent systems, and professional services by our team of specialists.

We are always inspired by the need to evolve and stay ahead of the ever-changing marketplace.

Designed for better corrosion resistance

Sampling system made of Super Duplex (SDSS) are designed to provide better corrosion resistance, particularly chloride stress corrosion and chloride pitting corrosion, and higher strength than standard austenitic stainless steels such as Type 304 or 316. The main differences in composition, when compared with an austenitic stainless steel is that the duplex steels have a higher chromium content, 20–28%; higher molybdenum, up to 5%; lower nickel, up to 9% and 0.05–0.50% nitrogen. Both the low nickel content and the high strength (enabling thinner sections to be used) give significant cost benefits. They are therefore used extensively in the offshore oil and gas industry for pipework systems, manifolds, risers, etc. and in the petrochemical industry in the form of pipelines and pressure vessels.

Enjoy the full benefits of an experienced team of passionate professionals who design Super Duplex (SDSS) sample connections

Mechatest employees possess decades of experience and knowledge to design the best solutions for your FPSO vessels. All of which is at your disposal when your Super Duplex (SDSS) sampling system needs adaptations, maintenance or repairs. Our staff has high-tech equipment at their disposal, thus increasing their efficiency even more. We are even capable of designing and manufacturing FPSO Super Duplex (SDSS) sampling in accordance with foreign codes and standards.

Start improving by sampling process today

Why wait any longer? Improvement starts today if you pick up the phone and call us at +31 (0)15 – 310 51 83. Our staff provides you with all the information you need to make an informed decision and choose the best sampling systems for liquid or liquefied gas.

also view

schramm polyester cabinets | sentry sample cooler | spot sampling

Contact us

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |